5 Ways Create Control Chart

Introduction to Control Charts

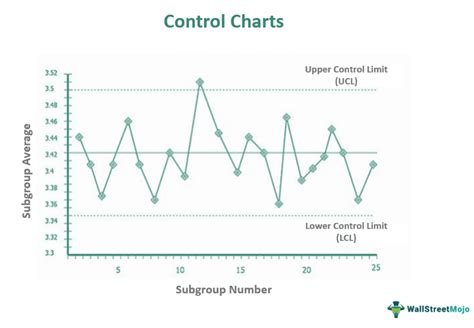

Control charts are a crucial tool in statistical process control, used to monitor and control processes in various industries, including manufacturing, healthcare, and finance. They help in detecting any deviations or anomalies in the process, allowing for prompt corrective actions. A control chart typically consists of a center line, an upper control limit, and a lower control limit. In this blog post, we will discuss the steps to create a control chart, highlighting five essential methods.

Understanding the Basics of Control Charts

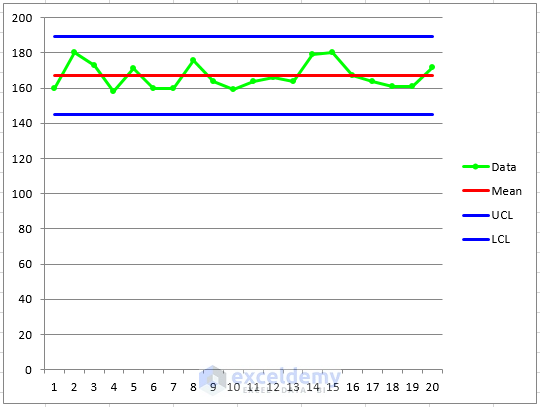

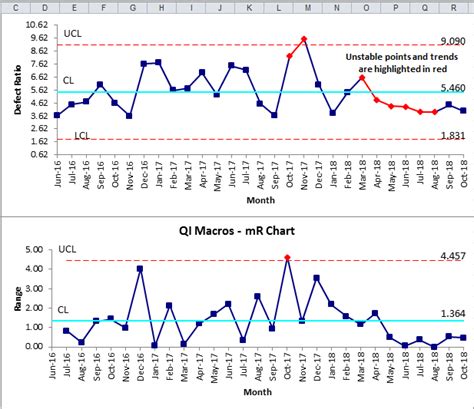

Before diving into the creation process, it’s essential to understand the basic components of a control chart. These include: * Center Line (CL): The average or mean value of the process. * Upper Control Limit (UCL): The maximum acceptable value of the process. * Lower Control Limit (LCL): The minimum acceptable value of the process. * Control Limits: These are usually set at 3-sigma (three standard deviations) from the center line.

5 Ways to Create a Control Chart

Here are the five methods to create a control chart:

- Manual Calculation Method: This involves manually calculating the center line, upper control limit, and lower control limit using historical data. It’s a time-consuming process but provides a thorough understanding of the control chart’s components.

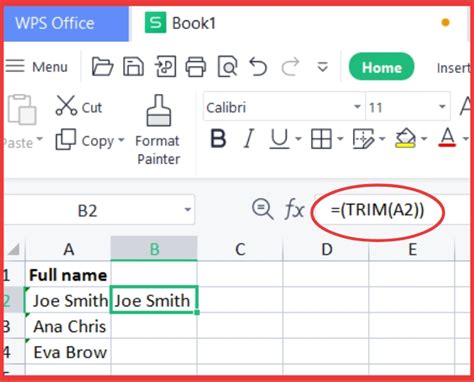

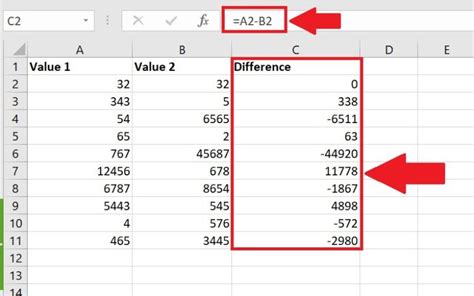

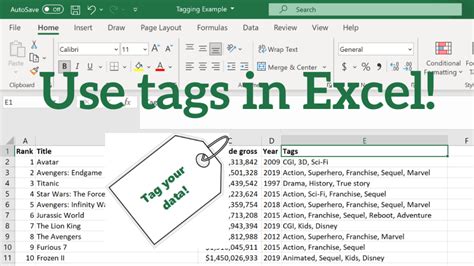

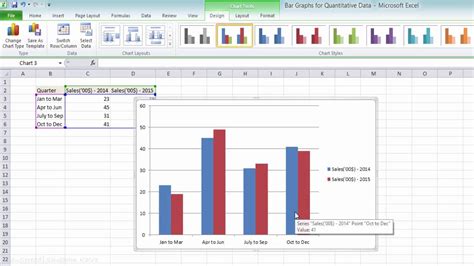

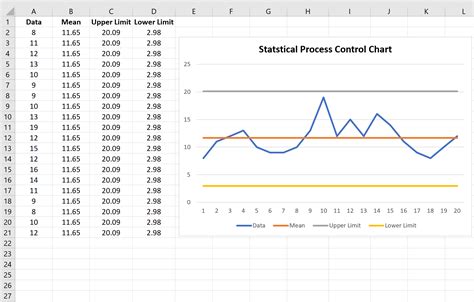

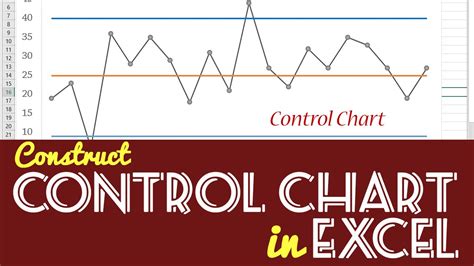

- Microsoft Excel Method: Microsoft Excel offers a range of tools and formulas to create control charts. You can use the AVERAGE function to calculate the center line and the STDEV function to calculate the standard deviation.

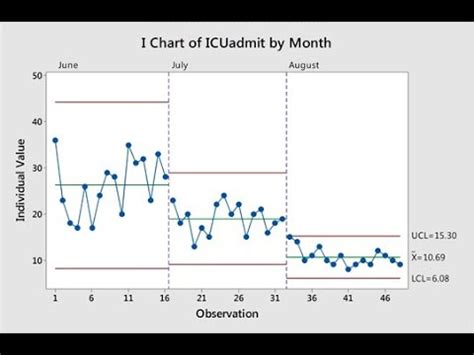

- Minitab Method: Minitab is a statistical software package that provides a range of tools for creating control charts. It offers a Control Chart module that allows you to easily create and customize control charts.

- R Method: R is a programming language and environment for statistical computing and graphics. It offers a range of packages, including qcc, which provides functions for creating control charts.

- Python Method: Python is a popular programming language that offers a range of libraries, including matplotlib and scipy, which can be used to create control charts.

Step-by-Step Guide to Creating a Control Chart

Here’s a step-by-step guide to creating a control chart using the manual calculation method: * Collect historical data: Collect a sufficient amount of historical data to calculate the center line and control limits. * Calculate the center line: Calculate the average or mean value of the process using the formula: CL = (Σx) / n, where x is the individual data point and n is the number of data points. * Calculate the standard deviation: Calculate the standard deviation of the process using the formula: σ = √[(Σ(x - CL)^2) / (n - 1)]. * Calculate the control limits: Calculate the upper and lower control limits using the formulas: UCL = CL + 3σ and LCL = CL - 3σ.

📝 Note: It's essential to regularly review and update the control chart to ensure that it remains effective in monitoring and controlling the process.

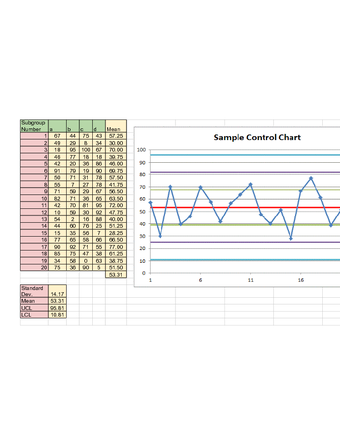

Example of a Control Chart

Here’s an example of a control chart:

| Sample Number | Value | Center Line | UCL | LCL |

|---|---|---|---|---|

| 1 | 10 | 12 | 18 | 6 |

| 2 | 12 | 12 | 18 | 6 |

| 3 | 15 | 12 | 18 | 6 |

Benefits of Control Charts

Control charts offer several benefits, including: * Improved Process Control: Control charts help in detecting any deviations or anomalies in the process, allowing for prompt corrective actions. * Increased Efficiency: Control charts help in reducing waste and improving efficiency by identifying areas for improvement. * Enhanced Quality: Control charts help in ensuring that the process is operating within acceptable limits, resulting in enhanced quality.

In summary, creating a control chart is a straightforward process that involves understanding the basics of control charts, selecting a method, and following a step-by-step guide. By using control charts, organizations can improve process control, increase efficiency, and enhance quality.

What is the purpose of a control chart?

+

The purpose of a control chart is to monitor and control processes in various industries, detecting any deviations or anomalies and allowing for prompt corrective actions.

What are the basic components of a control chart?

+

The basic components of a control chart include the center line, upper control limit, and lower control limit.

What are the benefits of using control charts?

+

The benefits of using control charts include improved process control, increased efficiency, and enhanced quality.