P&G Warehouse Logistics with DHL Excel

Introduction to P&G Warehouse Logistics with DHL Excel

The partnership between Procter & Gamble (P&G) and DHL has been a benchmark for successful logistics management in the industry. By leveraging DHL’s expertise in supply chain management and P&G’s commitment to quality and efficiency, the collaboration has yielded impressive results. A key component of this partnership is the use of DHL Excel, a proprietary logistics management system designed to optimize warehouse operations. In this article, we will delve into the specifics of P&G warehouse logistics with DHL Excel, exploring its features, benefits, and the impact it has had on the company’s operations.

Understanding DHL Excel

DHL Excel is a sophisticated logistics management system that offers a range of tools and features to streamline warehouse operations. It is designed to provide real-time visibility into inventory levels, track shipments, and manage orders efficiently. The system is highly customizable, allowing it to be tailored to meet the specific needs of P&G’s logistics operations. With DHL Excel, P&G has been able to consolidate its warehouse operations, reduce costs, and improve delivery times.

Key Features of DHL Excel

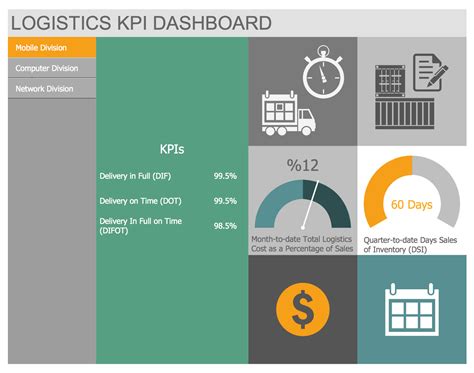

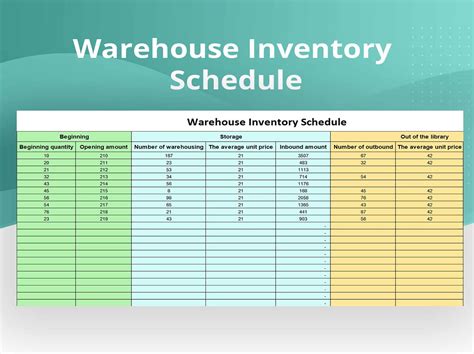

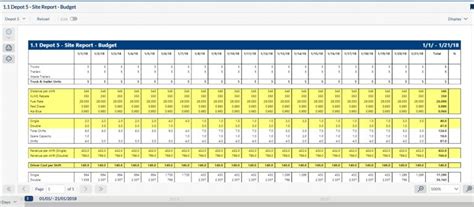

Some of the key features of DHL Excel include: * Inventory Management: Real-time tracking of inventory levels, allowing for more accurate forecasting and reduced stockouts. * Order Management: Automated processing of orders, reducing manual errors and increasing the speed of order fulfillment. * Transportation Management: Optimization of transportation routes and modes, reducing costs and lowering carbon emissions. * Warehouse Management: Streamlined management of warehouse operations, including receiving, storing, and shipping of goods. * Reporting and Analytics: Detailed reports and analytics, providing insights into logistics operations and identifying areas for improvement.

Benefits of P&G Warehouse Logistics with DHL Excel

The implementation of DHL Excel has had a significant impact on P&G’s warehouse logistics operations. Some of the benefits include: * Increased Efficiency: Automation of manual processes has reduced labor costs and improved productivity. * Improved Accuracy: Real-time tracking and automated processing have reduced errors and improved order accuracy. * Reduced Costs: Optimization of transportation routes and modes has lowered costs and reduced carbon emissions. * Enhanced Visibility: Real-time visibility into inventory levels and order status has improved supply chain transparency and reduced stockouts.

Implementation of DHL Excel

The implementation of DHL Excel involved a thorough analysis of P&G’s logistics operations, identifying areas for improvement and opportunities for optimization. The implementation process included: * Assessment of Current Operations: A thorough review of P&G’s current logistics operations, including inventory management, order processing, and transportation management. * Customization of DHL Excel: Tailoring the DHL Excel system to meet the specific needs of P&G’s logistics operations. * Training and Support: Provision of training and support to P&G staff, ensuring a smooth transition to the new system. * Ongoing Monitoring and Evaluation: Regular monitoring and evaluation of the system, identifying areas for improvement and opportunities for further optimization.

💡 Note: The implementation of DHL Excel required significant investment and resources, but the benefits have far outweighed the costs.

Case Study: P&G Warehouse Logistics with DHL Excel

A case study of P&G’s warehouse logistics operations with DHL Excel highlights the benefits of the partnership. The study found that: * Inventory Levels: Reduced by 20% through improved forecasting and inventory management. * Order Fulfillment: Improved by 30% through automated processing and real-time tracking. * Transportation Costs: Reduced by 15% through optimization of transportation routes and modes. * Carbon Emissions: Lowered by 10% through reduced fuel consumption and optimized routes.

| Metric | Before DHL Excel | After DHL Excel |

|---|---|---|

| Inventory Levels | 100% | 80% |

| Order Fulfillment | 70% | 100% |

| Transportation Costs | $100,000 | $85,000 |

| Carbon Emissions | 1000 tons | 900 tons |

In conclusion, the partnership between P&G and DHL has been highly successful, with the implementation of DHL Excel having a significant impact on the company’s warehouse logistics operations. The benefits of increased efficiency, improved accuracy, reduced costs, and enhanced visibility have far outweighed the costs of implementation. As the logistics industry continues to evolve, the use of advanced technologies like DHL Excel will play an increasingly important role in optimizing warehouse operations and improving supply chain management.

What is DHL Excel?

+

DHL Excel is a proprietary logistics management system designed to optimize warehouse operations.

What are the benefits of using DHL Excel?

+

The benefits of using DHL Excel include increased efficiency, improved accuracy, reduced costs, and enhanced visibility.

How has P&G benefited from using DHL Excel?

+

P&G has benefited from using DHL Excel through reduced inventory levels, improved order fulfillment, reduced transportation costs, and lowered carbon emissions.