5 Tips Excel Laser Vision

Introduction to Excel Laser Vision

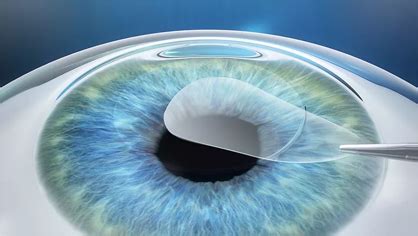

Excel Laser Vision is a cutting-edge technology that utilizes laser vision to enhance the accuracy and precision of various industrial and manufacturing processes. This innovative technology has revolutionized the way companies approach quality control, inspection, and material processing. In this article, we will delve into the world of Excel Laser Vision and explore its applications, benefits, and tips for optimal usage.

What is Excel Laser Vision?

Excel Laser Vision is a advanced technology that combines high-resolution cameras, sophisticated software, and precise laser systems to detect and analyze defects, irregularities, and other quality-related issues in materials and products. This technology is commonly used in industries such as automotive, aerospace, electronics, and pharmaceuticals, where high precision and accuracy are crucial.

Benefits of Excel Laser Vision

The benefits of Excel Laser Vision are numerous and significant. Some of the most notable advantages include: * Improved accuracy and precision: Excel Laser Vision enables companies to detect even the smallest defects and irregularities, ensuring that products meet the highest quality standards. * Increased efficiency: By automating the inspection process, Excel Laser Vision reduces the need for manual inspection, saving time and increasing productivity. * Enhanced quality control: Excel Laser Vision provides real-time feedback and analysis, allowing companies to identify and address quality issues promptly. * Reduced costs: By detecting defects early on, companies can avoid costly rework, scrap, and warranty claims. * Improved customer satisfaction: Excel Laser Vision helps companies deliver high-quality products that meet customer expectations, leading to increased customer satisfaction and loyalty.

5 Tips for Optimal Excel Laser Vision Usage

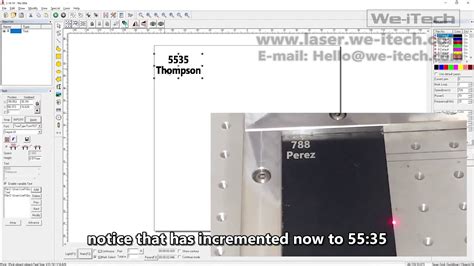

To get the most out of Excel Laser Vision, follow these 5 tips: * Tip 1: Proper System Calibration: Ensure that the Excel Laser Vision system is properly calibrated and configured for your specific application. This includes adjusting the laser settings, camera parameters, and software algorithms to optimize performance. * Tip 2: Material Selection: Choose the right materials for your application, taking into account factors such as reflectivity, transparency, and texture. This will help ensure that the Excel Laser Vision system can accurately detect and analyze defects and irregularities. * Tip 3: Environmental Control: Control the environment in which the Excel Laser Vision system operates, including factors such as lighting, temperature, and humidity. This will help minimize interference and ensure accurate results. * Tip 4: Operator Training: Provide comprehensive training to operators, ensuring that they understand the principles and operation of the Excel Laser Vision system. This includes training on system setup, calibration, and maintenance. * Tip 5: Regular Maintenance: Regularly maintain and update the Excel Laser Vision system, including software and hardware upgrades, to ensure optimal performance and accuracy.

💡 Note: Regular maintenance and calibration are crucial to ensuring the accuracy and reliability of the Excel Laser Vision system.

Applications of Excel Laser Vision

Excel Laser Vision has a wide range of applications across various industries, including: * Automotive: inspection of vehicle components, such as brakes, tires, and engine parts * Aerospace: inspection of aircraft components, such as wings, fuselage, and engine parts * Electronics: inspection of electronic components, such as PCBs, semiconductors, and displays * Pharmaceuticals: inspection of pharmaceutical products, such as tablets, capsules, and packaging

| Industry | Application |

|---|---|

| Automotive | Inspection of vehicle components |

| Aerospace | Inspection of aircraft components |

| Electronics | Inspection of electronic components |

| Pharmaceuticals | Inspection of pharmaceutical products |

In summary, Excel Laser Vision is a powerful technology that offers numerous benefits and applications across various industries. By following the 5 tips outlined in this article, companies can optimize their usage of Excel Laser Vision and improve their quality control, inspection, and material processing capabilities.

What is Excel Laser Vision?

+

Excel Laser Vision is a cutting-edge technology that utilizes laser vision to enhance the accuracy and precision of various industrial and manufacturing processes.

What are the benefits of Excel Laser Vision?

+

The benefits of Excel Laser Vision include improved accuracy and precision, increased efficiency, enhanced quality control, reduced costs, and improved customer satisfaction.

What are the applications of Excel Laser Vision?

+

Excel Laser Vision has a wide range of applications across various industries, including automotive, aerospace, electronics, and pharmaceuticals.